WJE PROJECTS

Turning Basin Terminal

CLIENT |

Port of Houston Authority |

LOCATION |

Houston, TX |

Structural Condition Assessment

In 2014, the Port of Houston Authority retained WJE to evaluate the existing conditions of seven of the above- and below-deck and underwater wharves at Turning Basin Terminal. As part of the first phase, our engineers performed condition assessments of the reinforced concrete elements, steel and timber fender systems, steel sheet pile and timber bulkheads, cleats, and bollards for seven wharves. We were also retained to develop repair documents for one of the wharves.

BACKGROUND

The Turning Basin Terminal is a multipurpose complex of thirty-five wharves located eight miles from downtown Houston. The wharves were constructed at various periods ranging from the 1910s to the 1980s and generally consist of elevated reinforced-concrete decks with steel-framed fender systems. The docks are equipped to handle various containerized or heavy-lift cargoes. The length of each wharf varies from approximately 400 feet to 600 feet.

SOLUTION

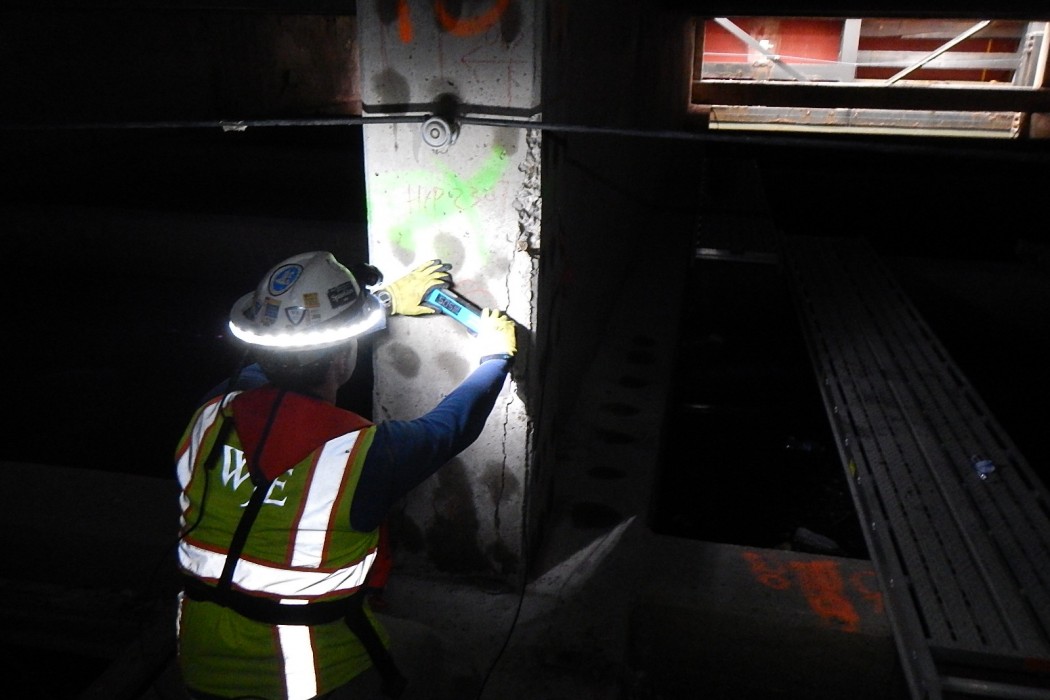

WJE’s overall assessment identified deterioration, such as cracks, spalls, delaminations, efflorescence, impact damage, and scour. We mechanically sounded surfaces using hand-held hammers, chains, and other mechanical impactors to identify areas of deterioration. Plannotate was used to document field conditions and tag photographs to locations of interest. Half-cell potential surveys were also performed on various elements to identify the propensity for corrosion of the reinforcing bars. Select portions of the wharves were also evaluated further to determine allowable load capacity and anticipated service life.

We performed an evaluation of the existing steel coating systems and conducted nondestructive thickness measurements of steel components to identify the severity of corrosion. Drilled core samples and steel coupon samples were obtained for laboratory testing.

We were further retained to develop complete concrete and steel rehabilitation design documents for one of the wharves, including quality assurance and quality control requirements incorporating inspection and hold point requirements. We also provided construction administration services to ensure quality assurance and integrity of the repair efforts.