WJE PROJECTS

Moses Lake Tide Gate

CLIENT |

Galveston County |

LOCATION |

Galveston COunty, TX |

Condition Assessment

The lower ten feet of the gate were replaced in 2005, and a new coating system for structural steel components was installed. Repairs in 2016 and 2019 replaced bearings, races, and seals at the cable pulleys at the top of the gate and addressed damaged sheaves. Galveston County was awarded funding from the U.S. Army Corps of Engineers (USACE) to help ensure the continued functionality of the Texas City Hurricane Levee. The County used part of this funding to address the Tide Gate’s failing coating and corrosion at the lower portion of the gate.

BACKGROUND

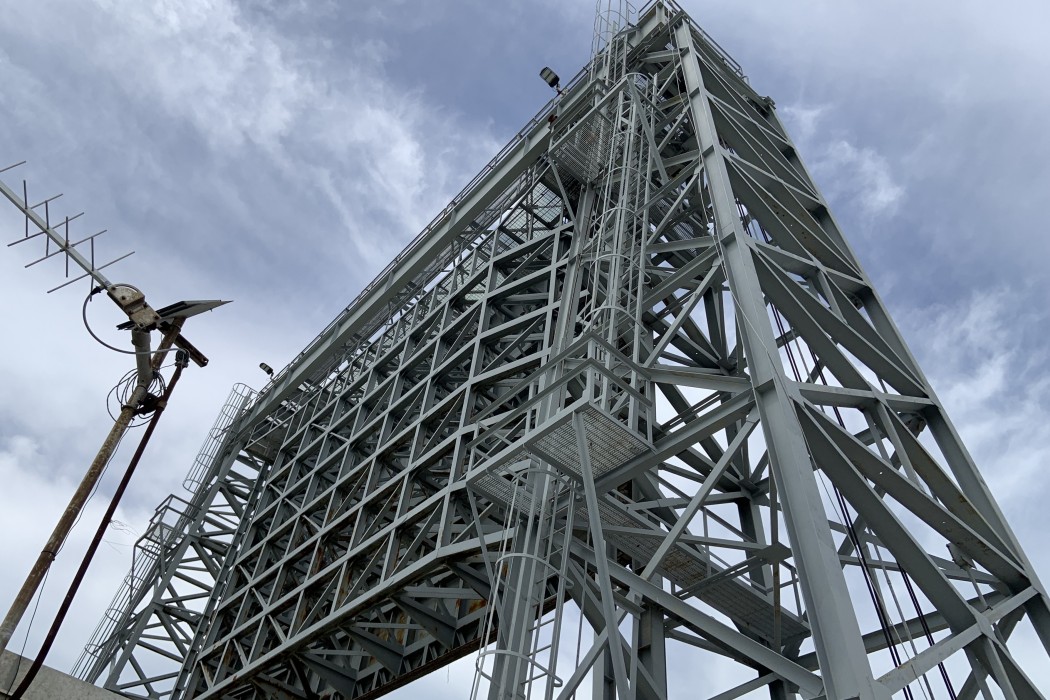

Moses Lake Tide Gate (Tide Gate) is located on the western shore of Galveston Bay at Miller Point in northern Galveston County. Tide Gate was designed in 1966 by USACE to provide hurricane protection and flood control to local homes. Tide Gate is a 56-foot-wide channel opening composed of east and west towers, a bridge, and liftgate. It is constructed of steel framing and paneling. Tide Gate is controlled by a mechanical and electrical system located in machinery and control houses.

SOLUTION

WJE performed a structural steel, mechanical, and electrical assessment of Tide Gate. The steel structure assessment consisted of an above-water, arms-length visual survey of the structural steel framing and the associated coating system of each tower, bridge, and liftgate. The coating investigation included nondestructive evaluation techniques and material extraction for laboratory study. The field assessment was performed from the ground level and accessible portions of the structure by rope access techniques.

The towers and bridge exhibited limited and localized distress, primarily consisting of corrosion at edges and crevices, connection distress, pitting or freckled rust, and coating delamination. The liftgate had similar distress, though it was more widespread. The observed distress was most severe on the portion of the liftgate that is submerged and located within the splash zone when Tide Gate is lowered. The existing coating was generally intact, but the observed deterioration and areas with lower adhesion values suggest it is nearing the end of its practical life. Elevated levels of distress to the coating system were visually apparent at the bottom twenty feet of the space frame. We recommended repair and coating options to extend the service life of Tide Gate, which included recoating the steel (in the atmospheric and submerged/splash zones), localized replacement, partial replacement, and full replacement of the gate.

RELATED INFORMATION

-

MORE >Markets | Marine Infrastructure

MORE >Markets | Marine Infrastructure -

MORE >Markets | Marine Repair and Rehabilitation Design

MORE >Markets | Marine Repair and Rehabilitation Design -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation -

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation